How Automation Trends Influence Hand Soldering, Rework, and Repair

11:17 - 08/01/2022

How Automation Trends Influence Hand Soldering, Rework, and Repair

Some images at VIMF 2024 exhibition

VIMF BAC NINH 2024 – Vietnam Industrial & Manufacturing Exhibition 2024

Samsung will invest an additional 1.8 billion USD in Bac Ninh

Industrial Expo Hanoi 2024

How Automation Trends Influence Hand Soldering, Rework, and Repair

Joshua Edberg, Director of Global Marketing at OK International, the parent company of Metcal, a provider of benchtop soldering systems.

Republished from Welding Journal (September 2021) with permission of the American Welding Society (AWS).

The evolution of electronics and devices must keep pace to meet today’s operator challenges.

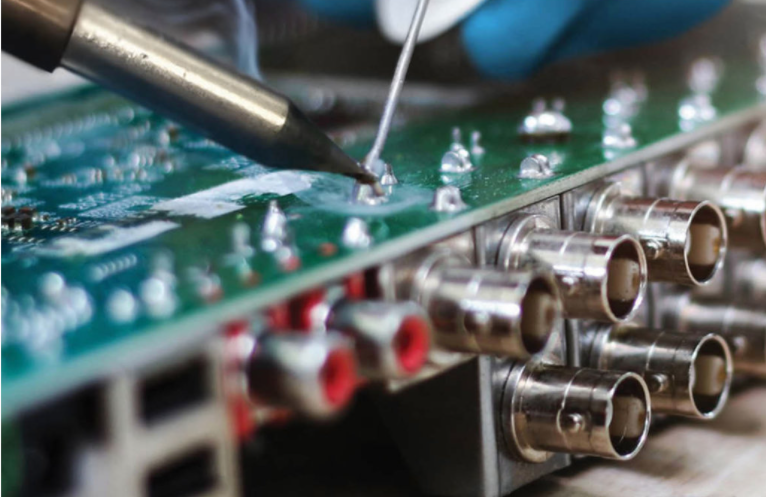

The evolution of electronics and devices must keep pace to meet today’s operator challenges. As technology in the electronics industry rapidly advances, electronic devices are getting smaller, faster, and more functional. Advanced printed circuit boards (PCBs) are now double-sided with stacked multiple layers. Thus, they are far more complex than conventional PCB designs and contain more components in tighter spaces, creating high-density interconnect (HDI) PCB configurations.

Automated assembly processes and automation equipment used in surface-mount technology (SMT) — such as pick-and-place robotics as well as wave and reflow soldering — have enabled rapid evolution in the electronics industry toward HDI PCBs and the miniaturization of components. The increasing use of automation has improved efficiencies and reduced manufacturing costs. It is also moving electronic assembly manufacturing closer to Industry 4.0, where data is fully documented, for full traceability, with lights-out manufacturing.

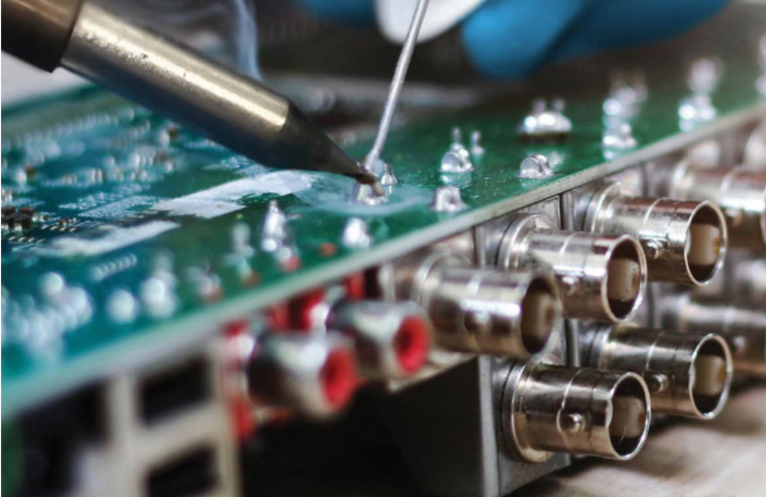

Despite this continuous movement, hand soldering is still necessary and still plays a key role in the manufacturing of electronic devices. Certain specialty, irregular, or heat-sensitive components must be hand soldered. With automation fulfilling the majority of electronic assembly operations, the remaining hand-soldering operations have become more challenging, requiring higher skilled soldering technicians, improved process controls, and advanced hand-soldering tools and equipment.

Although automated SMT assembly processes allow for the precise placement of components, these processes are not defect free. Issues such as bridging, tombstoning, slump, solder beading, insufficient solder, and damaged components require manual rework to repair or replace them. On high-density PCBs, components are not only exceedingly small but also extremely close together. Repairing electrical connections or removing and replacing small-scale chip packages must be done in very small spaces without damaging surrounding components. Specialized tools such as high-performance ultra-fine soldering tips, tweezers, and hand pieces are required for this type of high-precision rework, which often needs to be performed under a microscope or with the assistance of a camera to help accurately place, solder, and repair small-scale fine-pitch components.

Automated assembly processes and automation equipment used in surface-mount technology (SMT) — such as pick-and-place robotics as well as wave and reflow soldering — have enabled rapid evolution in the electronics industry toward HDI PCBs and the miniaturization of components. The increasing use of automation has improved efficiencies and reduced manufacturing costs. It is also moving electronic assembly manufacturing closer to Industry 4.0, where data is fully documented, for full traceability, with lights-out manufacturing.

Despite this continuous movement, hand soldering is still necessary and still plays a key role in the manufacturing of electronic devices. Certain specialty, irregular, or heat-sensitive components must be hand soldered. With automation fulfilling the majority of electronic assembly operations, the remaining hand-soldering operations have become more challenging, requiring higher skilled soldering technicians, improved process controls, and advanced hand-soldering tools and equipment.

Although automated SMT assembly processes allow for the precise placement of components, these processes are not defect free. Issues such as bridging, tombstoning, slump, solder beading, insufficient solder, and damaged components require manual rework to repair or replace them. On high-density PCBs, components are not only exceedingly small but also extremely close together. Repairing electrical connections or removing and replacing small-scale chip packages must be done in very small spaces without damaging surrounding components. Specialized tools such as high-performance ultra-fine soldering tips, tweezers, and hand pieces are required for this type of high-precision rework, which often needs to be performed under a microscope or with the assistance of a camera to help accurately place, solder, and repair small-scale fine-pitch components.

Another method of compensating for HTD challenges associated with highly metalized PCBs is preheating the circuit board and attempting to solder while the board is hot. This creates an ergonomic safety issue for soldering technicians. Specifically, preheating the PCB increases the risk of technicians getting burned during the soldering operation. And because the components are quite small, technicians tend to get closer to the PCB to better see their work, further increasing that risk.

Innovations in the industry, developed by manufacturers of soldering equipment, are addressing these challenges. These solutions include the use of inductive heating with adjustable temperature to improve performance, inductive SmartHeat® fixed temperature systems to remove the risk associated with operators adjusting the temperature, and specialized soldering software to communicate with operators to inform when connection validation or intermetallic compound formation is complete for high-quality solder joints.

Another area that manufacturers of hand-soldering equipment need to address ties to the loss of some level of traceability during the manufacturing process when automation is not used. Operations managers must understand such things as solder joint count, good vs. bad solder processes, number of consumables used, consumable life, and differences in productivity between operators to improve productivity, throughput, and cost management. Additionally, line managers need to get alerts to ensure that operators are following correct temperature management and utilizing correct tips and geometries, systems are working correctly, and electrostatic discharge events are properly recorded.

Integrated Internet of Things data-tracking systems can document associated solder joints with specific printed circuit board assemblies (PCBAs), thus filling this traceability hole. This can only happen if proper soldering technology is utilized on the manufacturing floor.

Today, manufacturers are offering such innovations as chip-in-cartridge technology to communicate proper geometries, solder joint validation software such as Connection Validation, fixed temperature cartridges, operator lockouts, and monitoring of power curves to start this process. As gateways and application software become more available, this will allow for managers on the floor to better understand what is happening from the hand-soldering processes.

With the evolution of electronic devices and their assembly methods, hand-soldering tools, equipment, and processes must keep pace to meet the daily challenges faced by today’s operators.